Saturday,

one of the most important HWS website has dedicated an article to TOA

!!

Don’t

You believe it?

See

now our page “ARTICLES” or click directly on www.woodensurfboards.blogspot.com

Thanks

again Grant !

|

Take

away extra material

|

|

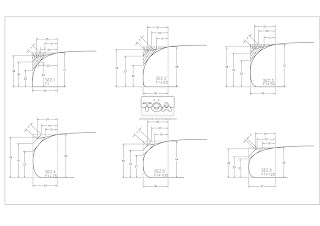

Six sections

|

|

A

long splint is very useful to link all points

|

|

Rail marked and ready for rasping

|

|

First

step completed

|

At

this stage the board is ready for building rails

|

First

samba layer has to be drilled to save weight

|

First

layer and pressing technique

|

First

layer and pressing technique

|

|

Remove

as material as possible to the first layer

|

|

Apply

glue to the first layer

|

|

Second

layer pressed with the same pressing technique

|

Once glued remove

extra wood

|

|

Cork

cutting operation

|

|

First

cork layer glued and clamped

|

|

surface

preparation before gluying blocks

|

|

Gluying

of the fin blocks in place

|

|

internal

fin blocks top view

|

Gluying

of the leash block in place

|

|

alignment

phase on the actual shape using paper template

|

|

preparation

& gluying of internal nose reinforcements

|

|

UP:

gluying of int. tail reinforcements DOWN:alignment and Gluying of

upper int rail reinforcements

|

|

before

& after wood carving

|

|

fish

tail takes shape..!

|